5mm Aeronautical Precision Machined Parts Complex Shape HRC45 Heat Treatment

5mm Aeronautical Precision Machined Parts Complex Shape HRC45 Heat Treatment Description

| Cnc Machining Or Not: | CNC Machining | Process: | Drilling/Bending/Stamping/Wire Cutting/Punching/Grinding/Welding |

|---|---|---|---|

| Sample: | Available | Drawing Format: | IGES,PDF,STEP. STP,DWG,X-T |

| Thickness: | 5mm | Name: | Precision Cnc Machining Parts |

| High Light: | cnc machined components, precision cnc machining parts | ||

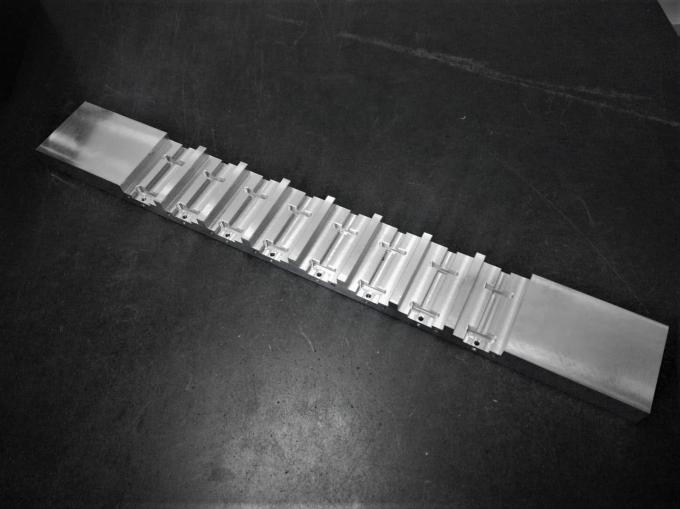

5mm Aeronautical Precision Machined Parts Complex Shape HRC45 Heat Treatment

Product details:

Customized CNC machining with 3 4 5 Axis linkage parts CNC milling service Precision

machined parts Aeronautical parts Complex shape parts

Material: 45# S45CSurface:Hardchrome plating Concentricity:0.03mm

Rugosity:Ra0.4 Tolerance:0.01-0.05mm Flatness:0.05mm

Thickness=5mm Verticality:0.03mm Heat Treatment=HRC45

L*W*H(mm)=600mm*350mm*200mm,

Main Product Display:

Metal:Aluminum 2024,2A12,5052,6020,6061,6063,7075,45#,SKD11,DC53,SUS304,SUS136.Machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,Grinding machine,EDM.Surface treatment:nickel plating,chrome plating,anodizing.

Purpose:Semiconductor Machinery,Laser Cutting Equipment,Communication equipment,

Testing equipment,Medical equipment,Electronics equipment,agricultural machinery,

electrical appliances products,Electronic devices, SMT Industrial field, etc.Vessel, Military,

Security system, Medical, Instrument measurement,Optical fiber transmission, etc.Optical

Communication field,Communication Equipment parts,Various mould accessories.

Fishing gear parts,Sports Equipment Parts,Fitness Equipment Parts,

Photographic equipment parts,Furniture Hardware Parts,Mower Parts,Intelligent Robot Parts,

Processing all kinds of metal and plastic matenrials with the change of the times,the materials

chosen by customers are changing constantly,in order to meet the different material needs

of customers,we have accumulated a very rich and wide range of process characteristics

and technical know-how of mechanical processing of metal and non-metal materials through

continuous technological innovation and research and development.

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others |

| Heat Treatment | ||

| treatment | Conditioning treatment | High cycle quenching |

| Passivation | quenching treatment | Carburizing treatment |

| Stress Removal Passivation | Vacuum quenching treatment | salt-bath nitrocarburizing |

| Annealing treatment | Tempering | |

keyMachine Display:

Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable

metal component.our highly skilled and professional workforce is dedicated to satisfying the individual

needs of all our customers and various markets the serve.

| Processing type | ||

| CNC Machining | EDM | Gear working |

| Multi-Axis CNC Machining | Thread Processing | stamping |

| CNC Turning Service | wire cutting | laser cutting |

| CNC Milling/Turning Multiple | drilling | Parts Assemble |

| Tolerance | Outer diameter dimension 0.01mmInternal diameter dimension 0.01mmCenter distance dimension 0.01mmlength,width,high(cnc milling process)0.01mmsurface roughness Ra0.4a Run-out 0.01mmRoundness 0.01mm Flatness 0.01mm | Customized drawings | AutoCAD,JPEG,PDF,STP,IGS,and most other file formats are accepted. |

| Application | Precision machinging,Unmanned aerial vehicle & aerospace,Motor & pump,Robotics,medical devices,Optical communication,Rotary Union,Automotive,3D Face Recognition System,Tools and Fixtures,Gear & screw,hardware fasteners & Bolt & Shaft | Package | Paper cartons/plywood pallets/plywood boxes or according to customer's requirement |

Why are you choose us ?

1. Rich CNC machining experience.

XINYA was founded in 2008years, having a long history of 10 years.Full experience

accumulated in Precision CNC machining service on best qualityfor medical, communications,

photoelectric, auto parts processing,CNC Precisionmachining. Mechanical processing – heat

treatment – surface treatment andassembly, we are committed to offer you and one-stop solution .

2. We have do business with many foreign customers from Europe/North America/Aisa etc areas,

like we have cooperation with GE and SUMITOMO,CANON foraround 10years. No matter

how much the production is, we will take it seriouslyand do our best.

3. We have had 60 sets machining,including CNC automatic lathes imported fromJapan,

So this will help our company have bigger manufacturing capacity.To meet more customers'

precision request, we have CMM, PROJECTOR etc.Precision inspection instruments to

measuring our products.In order to ensure quality, we carry out strict first sample inspection,

processinspection, shipment inspection, and every process is strictly checked. We try

every means to prevent defective products from flowing into the nextprocess and customer place.

4. We offer OEM/ODM service with reasonable production techniques forcustomers to cut down

the cost. Our engineering team use the UG/PROE/SOLIDWORKS/MASTER etc software to

support our production techniques.

Quality policy

We understand that customer's satisfied with the quality and service is an important indicator

of successful companies.The way the company wins depends on high-precision machine for

high quality requirements of various components.We may not be able to get the lowest price,

but we will do our best to offer you the best quality products,we prefer to explain you about

the price for a while,but don't want to apologize for the quality of life.If only pursuit of profit,

we can reduce costs to achieve the purpose of fast sales,but we believe that only the perfect

quality is what we prided,is our biggest value embodiment.Our efforts and perseverance have

also been recognized and followed by more and more customers.This is the biggest motivation

for us to continue and move forward.Good quality,the only way to express our thanks!

Customer's requirement is our standard. In the long-term production process, we have

established a perfect quality management system, so that product quality can be controlled

steadily in the manufacturing process. We strictly enforce the operation rules and quality

standards from the aspects of material purchasing, R&D and design, process flow and

quality inspection, all of which originate from our unremitting pursuit of quality.

We can't give you the lowest price, we can only give you good quality. We would rather

explain the price to you for a while than apologize for the quality for a lifetime. If we only

want to pursue profits, we can achieve the goal of fast sales by reducing costs. But we think

that only perfect quality is our pride, in order to promise that we will not be proud of

short-term benefits. Selling the future, our efforts and persistence are recognized and

followed by more and more customers, which is the greatest driving force for us to continue

to move forward. We can not thank you, but only report quality.

| Quality Inspection Links and Inspection Items | Introduction of Various Quality Testing Instruments | ||

| 1.Inspection of raw materials | 3CMM | ||

| IQC Inspectors will inspect surface,size and matcertificate provided of materials. |  |

CMM can be defined as "a detector which can move in three directions. |  |