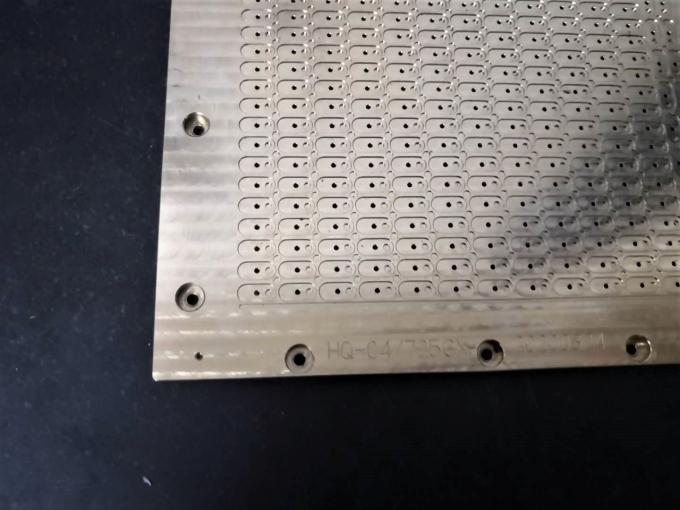

Anodizing Camera Lens SUS304 Inspection Fixture Components

Anodizing Camera Lens SUS304 Inspection Fixture Components Description

| Cnc Machining Or Not: | CNC Machining | Material: | Stainless Steel |

|---|---|---|---|

| Process: | Cnc Tuning,milling,cnc Machining | Application: | 3C Part |

| Product Name: | Customized OEM Custom Steel Cnc Precision Milling Jig Fixture | ||

| High Light: | SUS304 Inspection Fixture Components, Anodizing Inspection Fixture Components, CNC Jig And Checking Fixture | ||

OEM Mobile phone lens and Camera lens Inspection Fixture Components Jig

And Checking Fixture Antirust

Material: SUS304 L*W*H(mm)=230mm*200mm*15mm

Metal:SUS304,SUS316,SUS420,S136,Q235,A5052,A7075machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,

Grinding machine,EDM,wire cutting, Grinder, Bench, Metal plate.Surface treatment:Ni plating, Anodizing,etc.Purpose:Industrial using(Customization).Mobile phone assembly fixture,

Steaming fixture with optical lenses, Inspection fixture of Optical Communication Products,

Diamond Grinding fixture,Ceramic Products fixture,Electrical conduction inspection fixture,

Medical Wire Harness fixture,Auto parts assembly fixture,Aerospace Inspection and

Correction fixture….

| Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. | |||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | ||

| F141 | A7075 | Teflon | |||

| CK45 | Others | Others | |||

| Others | |||||

Main Machining Machinery Display

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

Quality policy

To focus on "customer satisfaction" as the premise condition of core business tenet, company personnel

to promote lean production management mode. With the evolution and development of precision metal

parts manufacturing industry chain, we recognized that the industrial chain of enterprise survival based

on quality and product services to guests. To this end, we continue to introduce foreign high-precision

processing and testing equipment; product process simple optimizing continuously; constantly improve

product quality standards and other aspects of enterprise management innovation, the company has won

high praise and affirmation from customers.

Our advantages:

1. Precision Cnc stainless steel parts strictly according to customer's drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. The most advanced CMM inspector to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedily&professional service

6. Give customer professional suggestion while in the process of customer designing to save costs.

Our freight price is often 30-50% lower than customer's

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to

shorten the sample production time

8. Quality assurance in accordance with ISO9001:2015