Anodizing CNC Turning Parts For Rechargeable Battery Cover Electronic Products

Anodizing CNC Turning Parts For Rechargeable Battery Cover Electronic Products Description

| Cnc Machining Or Not: | CNC Machining | Process: | Drilling/Bending/Stamping/Wire Cutting/Punching/Grinding/Welding |

|---|---|---|---|

| Service: | OEM/ODM/Customized/Design | Sample: | Available |

| Drawing Format: | IGES,PDF,STEP. STP,DWG,X-T | Material: | Brass,copper,Aluminum,Stainless Steel,etc |

| High Light: | precision turned components, precision turned parts | ||

Anodizing CNC Turning Parts For Rechargeable Battery Cover Electronic Products

Product details:

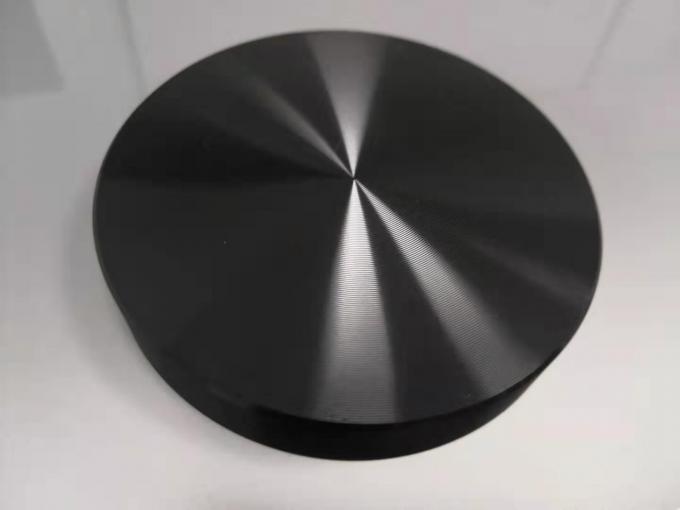

High Precision spiral patternCover Shell of Electronic Products Rechargeable battery Cover parts

Colour anodizing Appearance Parts Communication Equipment parts

Material: AL6061 Surface:Buleanodizing Rugosity:Ra0.8

Tolerance:0.02-0.05mmspiral pattern L*W*H(mm)=100mm*100mm*18.5mm,

Main Product Display:

Metal:Aluminum2024,2A12,5052,6020,6061,6063,7075,45#,SKD11,DC53,SUS304,SUS136.Machine:CNC lathe,Centering Machine,Multi-Axis turning,Surface treatment:nickel plating,chrome plating,anodizing.Purpose:Semiconductor Machinery,Laser Cutting Equipment,Communication equipment,

Medical equipment,agricultural machinery,electrical appliances products,Generator parts,

Bathroom Parts,Ship accessories,Electric Tool Parts,Monitoring equipment,Communication

Equipment,Audio Equipment Parts,Digital Camera Parts,Mining Machinery Parts,

Petroleum Mining Machinery Parts,Juice extractor parts,Mountaineering Equipment Parts,

Fishing gear parts,Sports Equipment Parts,Fitness Equipment Parts,Photographic

equipment parts,Furniture Hardware Parts,Mower Parts

Processing all kinds of metal and plastic matenrials with the change of the times,the materials

chosen by customers are changing constantly,in order to meet the different material needs

of customers,we have accumulated a very rich and wide range of process characteristics

and technical know-how of mechanical processing of metal and non-metal materials through

continuous technological innovation and research and development.

| Steel | Stainless steel | Aluminum | Copper | Plastic |

| 1.2344 | SUS303 | A1050 | C1020 | PC |

| SUJ2 | SUS304 | A2017 | C1100 | PP |

| 1095 | SUS316 | A2024 | C145 | MC |

| 1566 | SUS416 | A5052 | C5191 | ABS |

| S355 | SUS420J2 | A6020 | C1220 | PVC |

| C22 | SUS430 | A6061 | C360 | PEEK |

| C45 | SUS630 | A6063 | Others | PMMA |

| F125 | 17-4PH | A6082 | Bakelite | |

| CK45 | Others | Others | ||

| Others |

| Heat Treatment | ||

| treatment | Conditioning treatment | High cycle quenching |

| Passivation | quenching treatment | Carburizing treatment |

| Stress Removal Passivation | Vacuum quenching treatment | salt-bath nitrocarburizing |

| Annealing treatment | Tempering | |

KeyMachine Display:

Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient

and affordablemetal component.our highly skilled and professional workforce is dedicated

to satisfying the individualneeds of all our customers and various markets the serve.

| Processing type | ||

| CNC Machining | EDM | Gear working |

| Multi-Axis CNC Machining | Thread Processing | stamping |

| CNC Turning Service | wire cutting | laser cutting |

| CNC Milling/Turning Multiple | drilling | Parts Assemble |

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.2a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

Why are you choose us ?

1) We have our own factories, quality can be controlled seriously.

2) We Specialize in manufacturing about10 years.

3) We have professional testing department and testing equipment.

4) We have 12 rich experience engineers & 20 senior technicians.

5)We believe Reasonable price = High quality + Best service.

QC System:

1) Confirmed all drawings with customer and design the production way.

2) Checking the raw material before coming into our warehouse.

3) Confirmed the samples, reports of material and specs with customer.

4) Checking the process, machine, and other details in the production line.

5) Checking every products before packing them.

FAQ:

Q1:Are you a manufacturer?

A1:Yes, we are a medium size ISO9001 certificated manufacturer with a wide range of advanced

equipment.Warmly welcome to visit our factory so that you can make sure this point.

Q2:What is the MOQ?

A2:Minimum Order Quantity is one piece/set.If you require more qty,the price can be more competitive.

Q3:Can you do the mass production?

A3:Yes,we are a factory which can provide service of precision CNC machining, rapid prototyping,

wire cutting, tooling building and etc.After you confirm the samples, we can start mass production.

It is very convienient for customers to

Choose us as a one-stop solution supplier.

Q4:Which 3D drawing files should go with the machines?

A4:CNC machines only read *IGS,*STP,*STEP,*IGES,*X-T format, for *STL format,it goes with 3D

printer and SLA.

Q5:Is it possible to know how are my products going on without visiting your company?

A5:We will offer a detailed production schedule and send weekly reports with pictures or videos

which show the machining progress.

Q6:Will my drawings be safe after sending to you?

A6:Yes, we will keep them well and not release to third party without your permission.

Q7:What shall we do if we do not have drawings?

A7:Please send your sample to our factory,then we can copy or provide you better solutions.

Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be

made for you if placed order.

Quality policy

Quality manufacturing we strive for perfection,we maintain good technical

interaction with suppliers and customers with efforts to drive for quality excellence in our products,

we take pride in every of our manufacturing and management process to eliminate errors and

deficiencies .

We understand that customer's satisfied with the quality and service is an important indicator of

successful companies.The way the company wins depends on high-precision machine for high

quality requirements of various components.

CMM

Projector

Hardness tester

Thread Ring Gauges

Pin Gauges

Micrometer

Vernier Caliper

Roughness machine