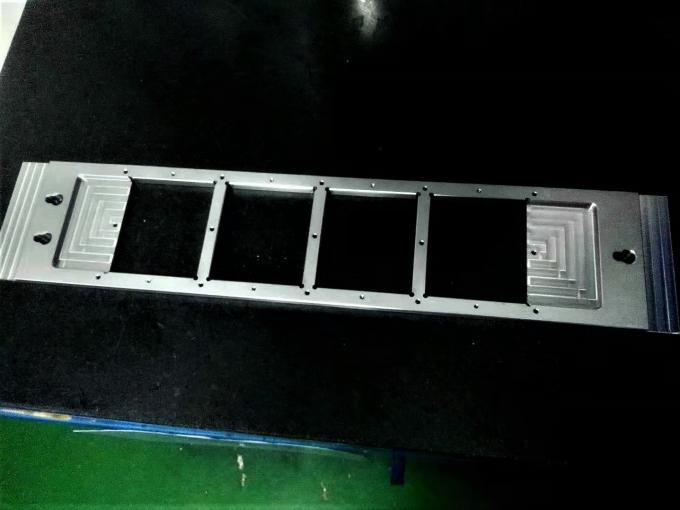

CNC Precision Machining Steaming Fixture For Optical Lenses Positioning

CNC Precision Machining Steaming Fixture For Optical Lenses Positioning Description

| Cnc Machining Or Not: | CNC Machining | Material: | Steel/stainless Steel/aluminum/brass |

|---|---|---|---|

| Surface Treatment: | Painting/powder Coating/anodized | Process: | Cnc Tuning,milling,cnc Machining |

| Name: | Fixture Making High Precision Aluminum Machining Jig Parts | Application: | Industrial Equipment,Auto Part/mechanical Parts/Electronic Parts |

| Tolerance: | 0.02mm | Product Name: | Customized OEM Custom Steel Cnc Precision Milling Jig Fixture |

| High Light: | cnc precision machining, cnc precision components | ||

CNC Precision Machining Steaming Fixture For Optical Lenses Positioning

Customized Stainless Steel Precision Steaming fixture for Optical LensesPositioning fixture

Jig fixture Tool ofAutomation Machine

Material: SUS304 Rugosity:Ra0.8 Tolerance:0.01-0.03mmFlatness:0.05mm L*W*H(mm)=380mm*90mm*15mm

Metal:1.2344,SUJ2,45#,F125,F141,CK45,SKD11,DC53,SLD,Q235,A5052,

SUS304,POM,PVC,steel,Al,section bar, electrical device,etc..machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,

Grinding machine,EDM,wire cutting, Grinder, Bench, Metal plate.Surface treatment:Ni plating,Purpose:Industrial using(Customization).Mobile phone assembly fixture,

Steaming fixture with optical lenses, Inspection fixture of Optical Communication Products,

Diamond Grinding fixture,Ceramic Products fixture,Electrical conduction inspection fixture,

Medical Wire Harness fixture,Auto parts assembly fixture,Aerospace Inspection and

Correction fixture….

Main Products Display

| Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. | |||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others | ||||

Key Production Equipment Display

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

Why are you choose us ?

| Fully reinforced | 10 Years of Practical Experience | High Quality, Best Cost |

| Professional production equipment more than 60 sets, imported CNC, Japan's Jinshang turning and milling machine, all cutting processing completed at one time. Annual production of precision spare parts more than 10 million pieces, annual sales of more than 50 million RMB. | We have a professional and experienced team, with more than 10 years of mechanical processing experience. For nearly 1000 enterprises, factories customize hundreds of thousands of products. Focus on more professional, we intentionally do a good job in every product, in return for customer trust in us. | High precision, high speed, high-end equipment, In the long-term production process, we have established a perfect quality management system, so that the quality of products can be controlled steadily in the manufacturing process. To strive for the highest level of product quality beyond customer expectations. |

| From trial production to mass production, 1PCS can also be ordered. | Surface treatment, heat treatment | Compliance with ROHS Directives |

| From trial production to batch production, the quantity is unlimited. For the sample for trial production and test, 1PCS can be ordered. Batch production of 20-30,000 also has sufficient capacity to meet production, on time delivery. | We not only provide precise mechanical processing, but also carry out various kinds of surface treatment and heat treatment according to the needs of customers. Provide one-stop service. | All kinds of raw materials and surface treatment fluids used meet the relevant requirements of ROHS REACH Directive, and can provide SGS and MSDS harmful substances detection report |

| Fastest response | Safe and Fast Logistics | Careful and meticulous service. |

| The fastest response, rapid delivery, strive for every minute and every second for customers. Quote quickly for 24 hours. Sample supply: Sample delivery period is 3-10 days. 365 days of production throughout the year. | All products are cleaned and rust-proof, and carefully packaged with cushioning materials and plastic suction boxes to ensure that nothing is wrong. Overseas logistics experience, FOB, CIF, DAP and other trade terms and air, sea, express and other logistics methods can be corresponding. | No matter the quantity of production, from trial production to batch production, we will take it seriously and do our best. Provide one-stop all-round service for mechanical processing, heat treatment, surface treatment and assembly. |

What is CNC?

The Basics Of CNC Machining

CNC (Computer Numerical Controlled) machining is a means to remove material with high precision

machines, using a wide variety of cutting tools to create the final design. Common CNC machines

include vertical milling machines, horizontal milling machines, lathes, and routers.

How CNC Machining Works

To successfully make a part on a CNC machine, skilled machinists create programmed instructions using

CAM (Computer Aided Manufacturing) software in conjunction with the CAD (Computer Aided Design)

model provided by the customer. The CAD model is loaded into the CAM software and tool paths are

created based on the required geometry of the manufactured part. Once the tool paths are determined,

the CAM software creates G-Code (machine code) that tells the machine how fast to move, how fast to

turn the stock and/or tool, and where to move the tool or workpiece in a 5-axis X, Y, Z, A, and B

coordinate system.

Our customers and markets

We Are Committed To Fulfilling Your Needs,We Are Proud Of Your Every Success

Quality policy

We specialize in machining parts and fabricating parts, with over 10 years manufacturing

and solutions experiences. We can offer you flexible solutions tailored to your precise demand.

Our complete quality control program protects our customers by assuring them of 100% test and

inspection prior to shipment. It is our promise that the purchased products are reliable, durable and

maintainable.Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient

and affordable metal component.our highly skilled and professional workforce is dedicate