CNC UAV Drone Parts Titanium TC4 TA9 TW340 Sand Blasting Surface Treatment

CNC UAV Drone Parts Titanium TC4 TA9 TW340 Sand Blasting Surface Treatment Description

| Name: | UAV Parts | Material Capabilities: | Aluminum,Stainless Steel,Brass,Steel Alloys |

|---|---|---|---|

| Surface Treatment: | Painting/sand Blasting/oiled Etc. | Process: | Turning/Milling/Grinding/Machining |

| Service: | Custom | Equipment: | CNC Machining Centres |

| High Light: | uav drone parts, aerospace parts | ||

CNC UAV Drone Parts Titanium TC4 TA9 TW340 Sand Blasting Surface Treatment

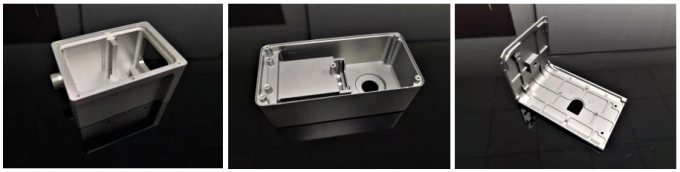

Customized Aluminum CNC Parts of UAV Unmaned Aerial Vehicle parts CNC Drone parts

metal CoverPrecision machined partsCamera Rotary Bracket

Material: AL6061 Surface:Anodizing Concentricity:0.03mm

Tolerance:0.01-0.05mm Flatness:0.01mm Thickness=0.5mm

Verticality:0.03mm L*W*H(mm)=80mm*100mm*100mm,

Metal:Titanium TC4,TA9,TW340,AL2012,AL2A12,AL6082,AL6061,AL7075,SUS303,SUS304Machine:CNC machinging center,CNC lathe,Wire cutting macine,Milling machine,Grinding machine,EDM.Surface treatment:sand blast,,anodizing,Engraving,Purpose:unmanned aerial vehicle,drone, UAV,UUV,Aerospace,Defense,Aircraft,guided missile,Submarine,

Navigation,

Main Products Display

| Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. | |||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| C45 | SUS630 | A6063 | Others | PMMA | Blacking |

| F125 | 17-4PH | A6082 | Bakelite | flame plating | |

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others | ||||

Main Machining Machinery Display

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

Production Capabilities Minimum Tolerance

Outer diameter dimension(turning Process) 0.01mm

Outer diameter dimension(centerless grinding process) 0.005mm

Outer diameter dimension(step grinding process) 0.005mm

Internal diameter dimension(turning process) 0.01mm

Center distance dimension( CNC milling process) 0.01mm

length,width,high(cnc milling process) 0.01mm

surface roughness Ra0.4a

Run-out 0.01mm

Roundness 0.01mm

Flatness 0.01mm

perpendicular 0.01mm

Cylindricity 0.01mm

Why are you choose us ?

1) We have our own factories, quality can be controlled seriously.

2) We Specialize in manufacturing about10 years.

3) We have professional testing department and testing equipment.

4) We have 12 rich experience engineers & 20 senior technicians.

5) Timely delivery and excellent service.

6) We believe Reasonable price = High quality + Best service.

QC System:

1) Confirmed all drawings with customer and design the production way.

2) Checking the raw material before coming into our warehouse.

3) Confirmed the samples, reports of material and specs with customer.

4) Checking the process, machine, and other details in the production line.

5) Checking every products before packing them.

6) Checking the package before delivery.

It is our goal to meet our customers’ expectation through good quality, fast delivery service, productivity and

Continuous improvement.Shenzhen Xinya Precsion machining Co., Ltd is to be your best choiceand long-term

partner.

FAQ:

Q: What do I need for offering a quote ?A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other

technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within24h.Q: What is your MOQ?A: MOQ depends on our client's needs for cnc machining parts, besides,we welcome trial order before

mass-production.Q: What is the production cycle?A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to

meet customers' requirement by adjusting our workshop schedule.Q: What kind of payment terms do you accept?A: T/T, Alipay, paypal, western union, moneygram etc.Q: Is it possible to know how is my product going on without visiting your company?A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos

which show the machining progress.Q: If you make poor quality goods,will you refund our payment?A: We make products according to drawings or samples strictly until them reach your 100% satisfaction.

And actually we wont take a chance to do poor quality products.We are proud of keeping the spirit of good quality.

If you have any further questions, please just feel free to contact me directly. I will try my best to service you

and your company. I hope we will be a good cooperation in the futuue.

Quality policy

With the rapid development of global economy, competition and challenges in various fields have become

inevitable. We are adhering to the firm spirit of enterprise and constantly pursue innovation, and are brave

enough to face and overcome all kinds of severe test.My team is consistently innovating and developing

our capability to align and meet the ever-changing market dynamics and technology advancement,

in providing efficient supply-chain &cost efficiency to our customers for their end—users. we strongly

believe in creating“win-win”synergy with our customers to build a long—term strategic partnership for

mutual growth.

Xinya precision — professional Precision metal parts industry for more than ten years

Continuously provide for you quality and speed try our best do everything

Marketr and Service

We Are Committed To Fulfilling Your Needs,We Are Proud Of Your Every Success