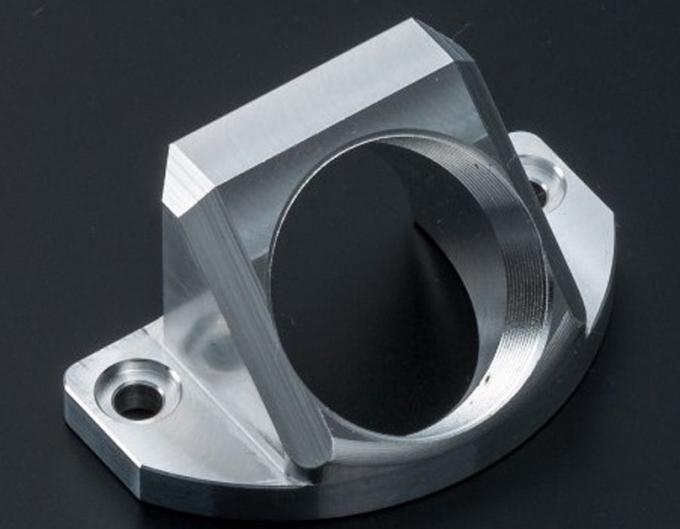

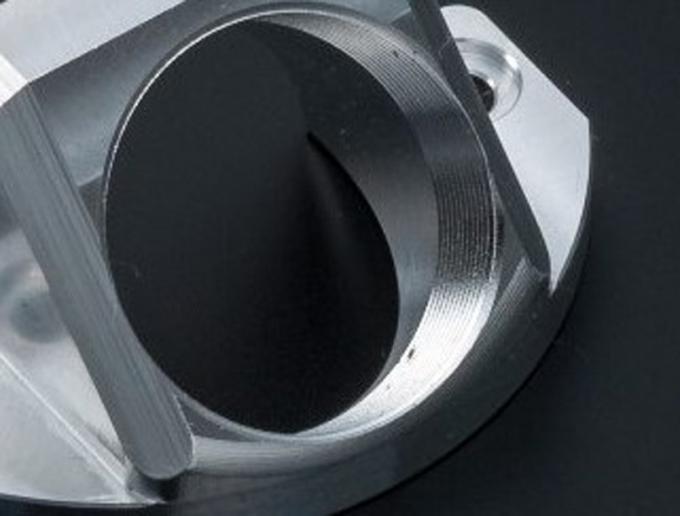

Customized 2D CNC Robot Mechanical Parts Aluminum Steel Alloys Material

Customized 2D CNC Robot Mechanical Parts Aluminum Steel Alloys Material Description

| Material Capabilities: | Aluminum,Steel Alloys,Brass,Copper | Product Name: | Customized Robotic Welding Fabrication CNC Mechanical Parts |

|---|---|---|---|

| Surface Treatment: | Anodized | Process: | CNC Turning/milling Process |

| Service: | Customized OEM | Drawing Format: | 2D/(PDF/CAD)3D(IGES/STEP) |

| High Light: | robot hardware components, robotic arm components | ||

Customized 2D CNC Robot Mechanical Parts Aluminum Steel Alloys Material

CNC Robot Mechanical parts Professional Service Robots Robot Componments

Rorotics Components Robot Mechanical parts

Material: AL6061 Surface:Anodizing Concentricity:0.01mmRugosity:Ra0.8 Tolerance:0.01-0.03mm Diameter:Ø30mmL*W*H(mm)=150mm*100mm*75mm

Metal:F141,A6061,A5056,POM,45#,SKD11,DC53,SLD,S136.Machine:CNC processing center,CNC lathe,Wire cutting macine,Milling machine,Grinding machine,EDM.Surface treatment:sand blast,nickel plating,chrome plating,anodizing.Purpose:Robotic,Robot Arm,Robot For House Recration,Professional Service Robots.Hvac Pipe Inspection Robots.

Domestic Robot,Robot for Transportation,Mechanical Robot.Industrial Robot,Humanoid Robot,Combat Robot Parts.

Main Products Display

Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by

customers are changing constantly,in order to meet the different material needs of customers,we have

accumulated a very rich and wide range of process characteristics and technical know-how of mechanical

processing of metal and non-metal materials through continuous technological innovation and research

and development.

| Steel | Stainless steel | Aluminum | Copper | Plastic |

| 1.2344 | SUS303 | A1050 | C1020 | PC |

| SUJ2 | SUS304 | A2017 | C1100 | PP |

| 1095 | SUS316 | A2024 | C145 | MC |

| 1212 | SUS403 | A5056 | C147 | POM |

| S355 | SUS420J2 | A6020 | C1220 | PVC |

| C22 | SUS430 | A6061 | C360 | PEEK |

| C45 | SUS630 | A6063 | Others | PMMA |

| F125 | 17-4PH | A6082 | Bakelite | |

| F141 | A7075 | Teflon | ||

| CK45 | Others | Others | ||

| Others |

Main Machining Machinery Display

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| EDM | Titanium plating | quenching treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

| Parts Assemble | phosphatizing | |

| Tolerance | Outer diameter dimension 0.01mmInternal diameter dimension 0.01mmCenter distance dimension 0.01mmlength,width,high(cnc milling process)0.01mmsurface roughness Ra0.4a Run-out 0.01mmRoundness 0.01mm Flatness 0.01mm | Customized drawings | AutoCAD,JPEG,PDF,STP,IGS,and most other file formats are accepted. |

Why are you choose us ?

Our advantages:

1. Precision Cnc stainless steel parts strictly according to customer's drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. The most advanced CMM inspector to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedily&professional service

6. Give customer professional suggestion while in the process of customer designing to save costs.

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee

to shorten the sample production time

8. Quality assurance in accordance with ISO9001:2015

It is our goal to meet our customers’ expectation through good quality, fast delivery service, productivity

andContinuous improvement.Shenzhen Xinya Precsion machining Co., Ltd is to be your best choiceand

long-termpartner.

FAQ:

Q1: Could you give me your best price?

A1: Of course yes, we are a professional manufacturer, so we could supply the best price without many

middlemen.

Q2: If my quantity is very small, could you do my products?

A2: Yes, we can. Do not worry about the quantity. We will provide different production ways based on

your quantity.

Q3: How long would the delivery time?

A3: It is based on all of your requirements about the products.

Q4: How can you guarantee the quality?

A4: We have a powerful QC team to control the quality in every production process. We believe the

best quality is our enterprise life. That’s why we have lots of big group companies.

Q5: I want to buy your products, how can I make the payment?

A5: We can accept the T/T and western union.

Q6: What are your mainly customers around the world?

A6: Our mainly customers are from North American, Western Europe and Japan.

Q7: I didn’t find the products I want, can you OEM for me?

A7: Yes, we are a professional OEM and ODM manufacturer with 10 years’ experiences. We can

OEM and ODM the products which you need. Our aim is “You have the idea, we turn it into products”

What is CNC?

The Basics Of CNC Machining

CNC (Computer Numerical Controlled) machining is a means to remove material with high precision

machines, using a wide variety of cutting tools to create the final design. Common CNC machines

include vertical milling machines, horizontal milling machines, lathes, and routers.

How CNC Machining Works

To successfully make a part on a CNC machine, skilled machinists create programmed instructions using

CAM (Computer Aided Manufacturing) software in conjunction with the CAD (Computer Aided Design)

model provided by the customer. The CAD model is loaded into the CAM software and tool paths are

created based on the required geometry of the manufactured part. Once the tool paths are determined,

the CAM software creates G-Code (machine code) that tells the machine how fast to move, how fast to

turn the stock and/or tool, and where to move the tool or workpiece in a 5-axis X, Y, Z, A, and B coordinate system.

Types Of CNC Machining

There are several types of CNC machine — namely the CNC lathe, CNC mill, CNC router, and Wire EDM

With a CNC lathe, the part stock turns on the spindle and the fixed cutting tool is brought into contact with

the workpiece. Lathes are perfect for cylindrical parts and are easily set up for repeatability. Conversely,

on a CNC mill the rotating cutting tool moves around the workpiece, which remains fixed to a bed. Mills

are all-purpose CNC machines that can handle most any machining process.CNC machines can be simple

2-axis machines where only the tool head moves in the X and Z-axes or much more complex 5-axis CNC mills,

where the workpiece can also move. This allows for more complex geometries without requiring extra operator

work and expertise. This makes it easier to produce complex parts and reduces the chance of operator error.

Wire Electrical Discharge Machines (EDMs) take an entirely different approach to CNC machining in that they

rely on conductive materials and electricity to erode the workpiece. This process can cut any conductive material,

including all metals.CNC routers, on the other hand, are ideal for cutting soft sheet materials such as wood and

aluminum and are more cost-effective than using a CNC mill for a similar job. For harder sheet materials such

as steel, a waterjet, laser, or plasma cutter is required.

Benefits Of CNC Machining?

The benefits of CNC machining are numerous. Once a tool path is created and a machine is programmed,

it can run a part 1 time, or 100,000 times. CNC machines are built for precise manufacturing and repeatability

which makes them cost-efficient and highly scalable.

If you have any further questions, please just feel free to contact me directly. I will try my best to service

you and your company. I hope we will be a good cooperation in the futuue

Marketr and Service

We Are Committed To Fulfilling