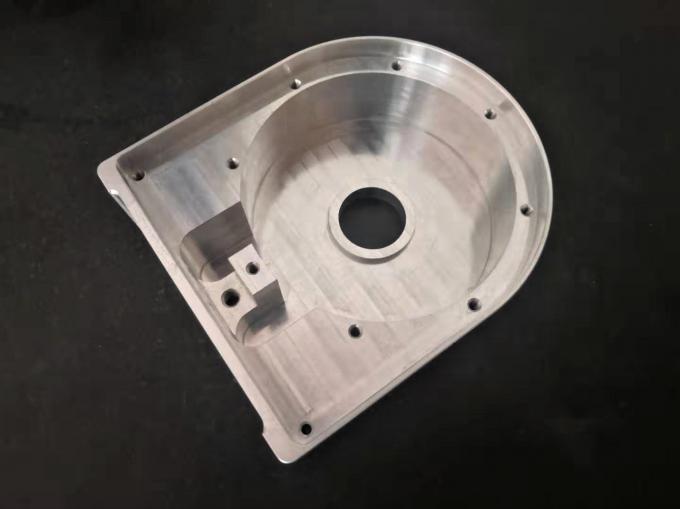

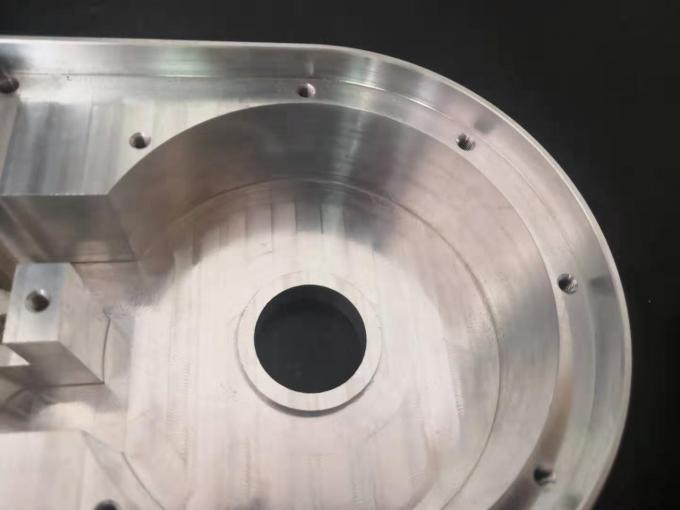

SS CNC Milling Parts Semiconductor Machinery Components 0.01mm Flatness

SS CNC Milling Parts Semiconductor Machinery Components 0.01mm Flatness Description

| Cnc Machining Or Not: | CNC Machining | Process: | Cnc Tuning,milling,cnc Machining |

|---|---|---|---|

| Application: | Industrial Equipment,medical,Auto Part/mechanical Parts/Electronic Parts | Product Name: | Customized OEM Custom Steel Cnc Precision Milling Jig Fixture |

| L*W*H(mm): | 240mm*110mm*45mm | Flatness: | 0.01mm |

| High Light: | cnc milling service, metal machining services | ||

SS CNC Milling Parts Semiconductor Machinery Components 0.01mm Flatness

Product Details:

CNC Milling Metal Parts of Experiment Stainless Steel Components Semiconductor Machinery parts

Ship accessoriesBridge structural parts

Material: SUS304 Rugosity:Ra0.2 Tolerance:0.01-0.03mm Flatness:0.01mm

Heat Treatment=HRC48L*W*H(mm)=240mm*110mm*45mm

Main Products Display:

Metal:2024,2A12,5052,6020,6061,6063,7075,45#,SKD11,DC53,SUS304,SUS136.SKD11,DC53.

Plastic(POM, PEEK, PP)

Machine:CNC processing center,Wire cutting macine,Milling machine,Grinding machine,EDM.Surface treatment:nickel plating,chrome plating,anodizing.

Purpose:Communication equipment,Testing equipment,Electronics equipment,agricultural

Electric Tool Parts,Monitoring equipment,Communication Equipment,Audio Equipment Parts,

Digital Camera Parts,Mining Machinery Parts,Petroleum Mining Machinery Parts,Bridge

Fishing gear parts,Sports Equipment Parts,Fitness Equipment Parts,Photographic equipment parts,

Furniture Hardware Parts,Mower Parts

| Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. | |||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS430 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS630 | A6020 | C1220 | PVC | Silver plating |

| C22 | A6061 | C360 | PEEK | Chrome Plated | |

| C45 | A6063 | Others | PMMA | Blacking | |

| F125 | A6082 | Bakelite | flame plating | ||

| F141 | A7075 | Teflon | Abrasion | ||

| CK45 | Others | Others | Chemical polishing | ||

| Others | Others | ||||

Main Machining Machinery Display

| Continuing to invest heavily in our facilities , we aim to bring you the most reliable,efficient and affordable metal component.our highly skilled and professional workforce is dedicated to satisfying the individual needs of all our customers and various markets the serve. | ||

| Processing type | surface treatment | Heat Treatment |

| CNC Machining | nickel plating | treatment |

| Multi-Axis CNC Machining | Gold plating | Passivation |

| CNC Turning Service | silver plating | Stress Removal Passivation |

| CNC Milling/Turning Multiple | chrome plating | Conditioning treatment |

| Parts Assemble | phosphatizing | Annealing treatment |

| Thread Processing | Blackening treatment | Vacuum quenching treatment |

| wire cutting | anodizing | High cycle quenching |

| drilling | Sandblasting | Carburizing treatment |

| Gear working | Chemical grinding | salt-bath nitrocarburizing |

| stamping | dacromet | Tempering |

| laser cutting | zinc plating | Annealing treatment |

| Mechanical Parts Design | powder coated | |

Why are you choose us ?