Straight Screw CNC Connector Parts CNC Turning Services Juice Extractor Parts

Straight Screw CNC Connector Parts CNC Turning Services Juice Extractor Parts Description

| Cnc Machining Or Not: | CNC Machining | Material Capabilities: | Aluminum,Stainless Steel,Steel Alloys |

|---|---|---|---|

| Surface Treatment: | Painting/sand Blasting/oiled Etc. | Process: | Turning/Milling/Grinding/Machining |

| Service: | OEM/ODM Service | Equipment: | CNC Machining Centres |

| High Light: | custom cnc parts, prototype cnc machining | ||

Straight Screw CNC Connector Parts CNC Turning Services Juice Extractor Parts

Precision connector Oil pressure parts Machining CNC Turning Services straight screw connector

Juice extractor parts

Material: 17-4PH Surface:Polishing Concentricity:0.03mm

Rugosity:Ra0.4 Tolerance:0.01-0.03mm Diameter:Ø28mm

Verticality:0.03mm L*W*H(mm)=28mm*28mm*20mm,

Metal:C22,C45,F141,1.2344,SUS303,SUS304,SUS316,30CrMn, Black Oxide Stainless Steel,

Solid Brass, and Silicon Bronze,Plastic.Machine:Multi-Axis turning,CNC lathe,CNC machinging center,.Surface polishing,zinc plating,brass plating,nickel plating,dacromet,electrophoresis,Passivation,

etc.Heat Treatment.Purpose:All kinds of machinery,Equipment,Vehicles,Ships,Railway,Bridges,Architecture,

Structure,Tools,Instruments,Electronic products,Medical instruments,optical instrument

Main Products Display

| Processing all kinds of metal and plastic matenrials with the change of the times,the materials chosen by customers are changing constantly,in order to meet the different material needs of customers,we have accumulated a very rich and wide range of process characteristics and technical know-how of mechanical processing of metal and non-metal materials through continuous technological innovation and research and development. | |||||

| Steel | Stainless steel | Aluminum | Copper | Plastic | Surface treatment |

| 1.2344 | SUS303 | A1050 | C1020 | PC | High speed sand blasting |

| SUJ2 | SUS304 | A2017 | C1100 | PP | Anodic oxidation |

| 1095 | SUS316 | A2024 | C145 | MC | Nickel plating |

| 1212 | SUS403 | A5056 | C147 | POM | Titanium plating |

| 1566 | SUS416 | A5052 | C5191 | ABS | Gold plating |

| S355 | SUS420J2 | A6020 | C1220 | PVC | Silver plating |

| C22 | SUS430 | A6061 | C360 | PEEK | Chrome Plated |

| CK45 | 17-4P | A6063 | Teflon | Blacking | |

| F125 | HOthers | A6082 | flame plating | ||

| F141 | A7075 | Chemical polishing | |||

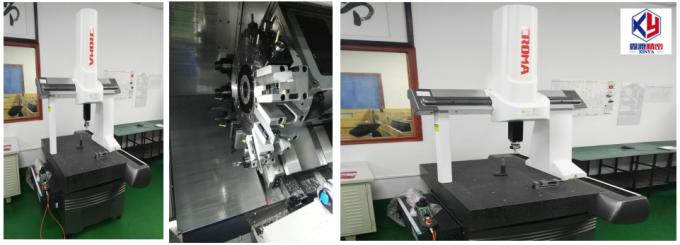

Main Machining Machinery Display

Latest technology including:

CNC Milling Service

CNC Turning Service

CNC Milling and Turning Multiple

Mechanical Parts Design

Precision Engineering Services

Parts Assemble

EDM-Wire Cutting

Laser Cutting

Precision Grinding

Auto-Lathing Turning

Injection Moulding

MIMMoulding

Die Casting

| Tolerance | Outer diameter dimension 0.01mmInternal diameter dimension 0.01mmCenter distance dimension 0.01mmlength,width,high(cnc milling process)0.01mmsurface roughness Ra0.4a Run-out 0.01mmRoundness 0.01mm Flatness 0.01mm | Customized drawings | AutoCAD,JPEG,PDF,STP,IGS,and most other file formats are accepted. |

| Application | Precision machinging,Unmanned aerial vehicle & aerospace,Motor & pump,Robotics,medical devices,Optical communication,Rotary Union,Automotive,3D Face Recognition System,Tools and Fixtures,Gear & screw,hardware fasteners & Bolt & Shaft | Package | Paper cartons/plywood pallets/plywood boxes or according to customer's requirement |

Quality policy

We understand that customer's satisfied with the quality and service is an important indicator of successful

companies.The way the company wins depends on high-precision machine for high quality requirements

of various components.We may not be able to get the lowest price,but we will do our best to offer you the

best quality products,we prefer to explain you about the price for a while,but don't want to apologize for the

quality of life.If only pursuit of profit,we can reduce costs to achieve the purpose of fast sales,but we believe

that only the perfect quality is what we prided,is our biggest value embodiment.Our efforts and perseverance

have also been recognized and followed by more and more customers.This is the biggest motivation for us

to continue and move forward.Good quality,the only way to express our thanks!

We Are Committed To Fulfilling Your Needs,We Are Proud Of Your Every Success.

Our advantages:

1. Precision Cnc stainless steel parts strictly according to customer's drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. The most advanced CMM inspector to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedily&professional service

6. Give customer professional suggestion while in the process of customer designing to save costs.

Our freight price is often 30-50% lower than customer's

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee

to shorten the sample production time

8. Quality assurance in accordance with ISO9001:2015

FAQ:

Q1: What do you need to make a quotation?

A1: To make a good quotation should be sure by the following things:

1. Existing samples or products drawings or 3D model data files.

2. Your request for products you are going to make, including quantity, material, finish.

Q2: How much time do you need to quote?

A2: Usually a quotation for a product is sent in 24 hours after we receive enquiry with all the necessary details

Q3: How long does it take to have products?

A3: It varies a little depending on product size and complexity of its shape and the quantity. We will give

our exact delivery time when you get the quotation.

Q4: How to know whether my products is being built on schedule?

A4: On clients' requests we are giving a detailed products building schedule and send weekly reports.

The report may have digital pictures that show the progress of work.

Q5: What guarantee that you will make them as good as we do?

A5: We can offer 1~3 pcs of samples to you for approval, if the quality is OK, and we will proceed our

business. We always inspect all specification shown on drawings, and we can offer Inspect Report to you.

Q6: What guarantee do we get that its made from the correct material?

A6: We can offer material certificates which will assure you we use correct material.

Q7: If you make parts and there are wrong do you refund out money?

A7: If the parts are wrong, we will return your money or we can make correct parts to you again.

Q8: How can you guarantee the quality?

A8: We have a powerful QC team to control the quality in every production process. We believe the best

quality is our enterprise life. That’s why we have lots of big group companies.

Q9: I want to buy your products, how can I make the payment?

A9: We can accept the T/T and western union.

Q10: What are your mainly customers around the world?

A10: Our mainly customers are from North American, Western Europe and Japan.

If you have any further questions, please just feel free to contact me directly. I will try my best to service you

and your company. I hope we will be a good cooperation in the futuue.